NSL系列自潤鏈條將油品浸入粉末冶金布斯,使鏈條運轉時保持潤滑狀態,達到免保養的目的,適用於要求潔淨的場所或是難以保養的設備。

| 關於NSL系列自潤鏈條

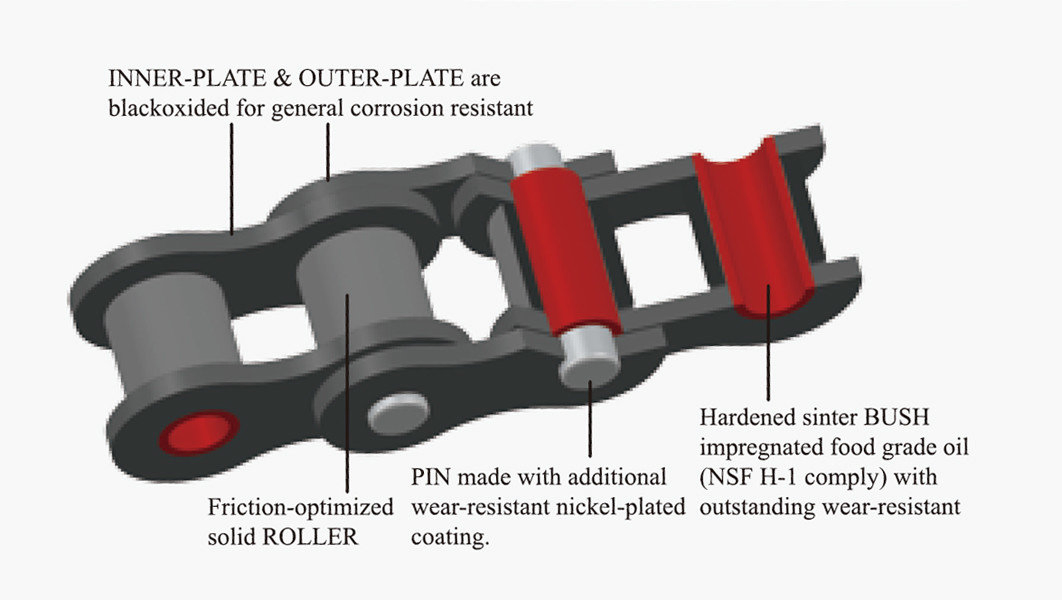

同時,我們的自潤鏈條使用鍍鎳小軸與無縫羅拉,提升鏈條耐磨耗,延長使用壽命。

鏈片為染黑處理,具有輕度防鏽性能。

零件皆經熱處理和噴砂處理提高強度和耐用性。

我們也針對不同易鏽環境,提供不同防鏽效果之防鏽塗層。

因此,透過延長鏈條壽命,減少維護成本與停機時間,以達到提高產量,節省時間和成本。

尤其對於不易潤滑的使用環境,我們非常推薦使用自潤鏈條。

此鏈條也非常適合用於食品,飲料設備或其它對清潔度和生產率有很高要求的產業。

| 兩種不同油品NSL自潤鏈條

我們提供兩種適用不同溫度範圍的自潤滾子鏈。

標準(FG):粉末冶金布斯使用NSF H1認證食品級油品,適用溫度-10°C〜145°C (14°F〜293°F)。

耐高溫(FGH):粉末冶金布斯使用NSF H1認證食品級油品,適用溫度-20°C〜220°C(-4°F〜428°F)。

| 選擇鏈條事項

1. 建議使用在輕負載或中等負載

2. 建議最快運行速度:

- 40 / 08B:150M /分鐘

- 50 / 10B:135M /分鐘

- 60 / 12B:120M /分鐘

- 100:80M /分鐘

- 120:50M /分鐘

3. 自潤鏈條可使用標準鏈輪

4. 可與標準滾子鏈互換使用,但請注意:

- 更換舊鏈條時,請務必更換整個鏈條

- 新鏈條不能與舊鏈條連接,也不能連接零件

| About Self-Lube Roller Chain - NSL Series

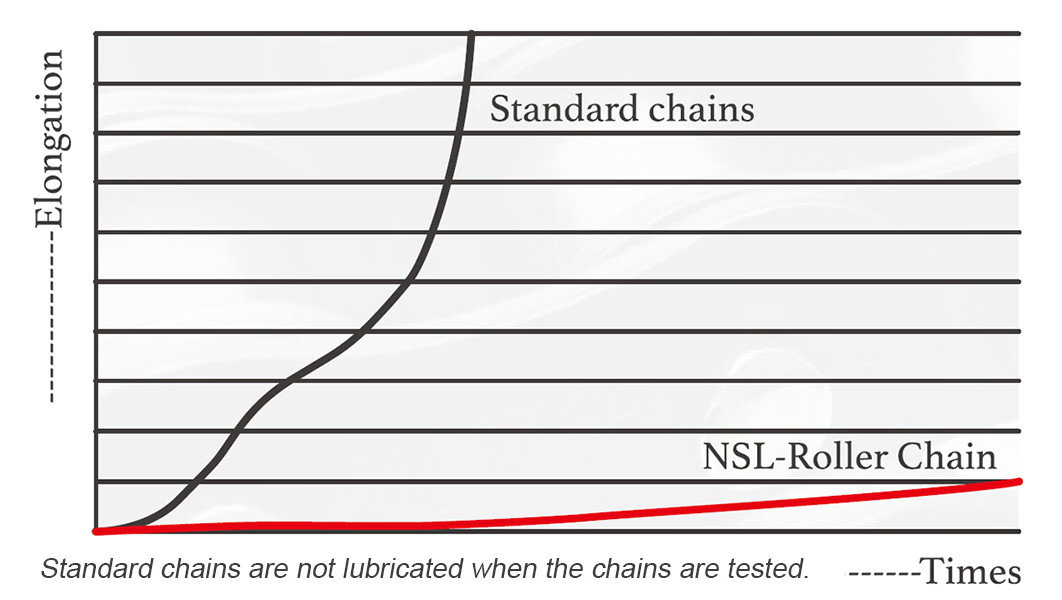

NSL Series chain is a lube free roller chain featuring sintered alloy bushings.

The sintered bush is porous metal structure and impregnated NSF H1 approved food grade oil by vacuum.

When the chain is running, the oil naturally come out from the bush to maintain the chain in lubricated state.

Also, our self-lube roller chain use nickel plated pins and solid rollers to increase wear life.

The plates are black oxide for slight corrosion resistance and components are heat treated and shot peened to boost strength and durability.

Other corrosion resistant coatings for tough environment are available.

The chain saves time and money by extending chain life and reducing maintenance costs for more production.

It is recommended for the place where lubricating is difficult.

Self-lube chain is also ideal for food, beverage equipment or any other industries where cleanliness and productivity are critical.

| Two Versions of NSL Self-Lube Roller Chains

We offer two versions of self-lube roller chains for different temperature range.

Standard (FG): utilizes NSF H1 approved oil impregnated bushings, temperature range from -10°C ~ 145°C (14°F~293°F).

Optional (FGH): utilizes NSF H1 approved oil impregnated bushings, temperature range from -20°C ~ 220°C (-4°F~428°F).

| Notes for Selection of Chain

1. Under light load or medium load

2. Maximum recommended operating speed:

- 40 / 08B: 150M / min

- 50 / 10B: 135M / min

- 60 / 12B: 120M / min

- 100: 80M / min

- 120: 50M / min